- About Us

-

Ex Training

Ex Training

-

Ex Training

Ex Training

-

Ex Training

-

Ex Consulting

Ex Consulting

-

Accreditation

Accreditation

- European Accreditation

- Korean Accreditation

-

Int'l Accreditation

Int'l Accreditation

-

Construction

Construction

-

Accreditation

-

Management System Consulting

Management System Consulting

- ISO Consulting

-

Occupational Safety & Environmental Consulting

Occupational Safety & Environmental Consulting

-

Occupational Safety Diagnosis

Occupational Safety Diagnosis

-

Ex Engineering

Ex Engineering

Ex Consulting

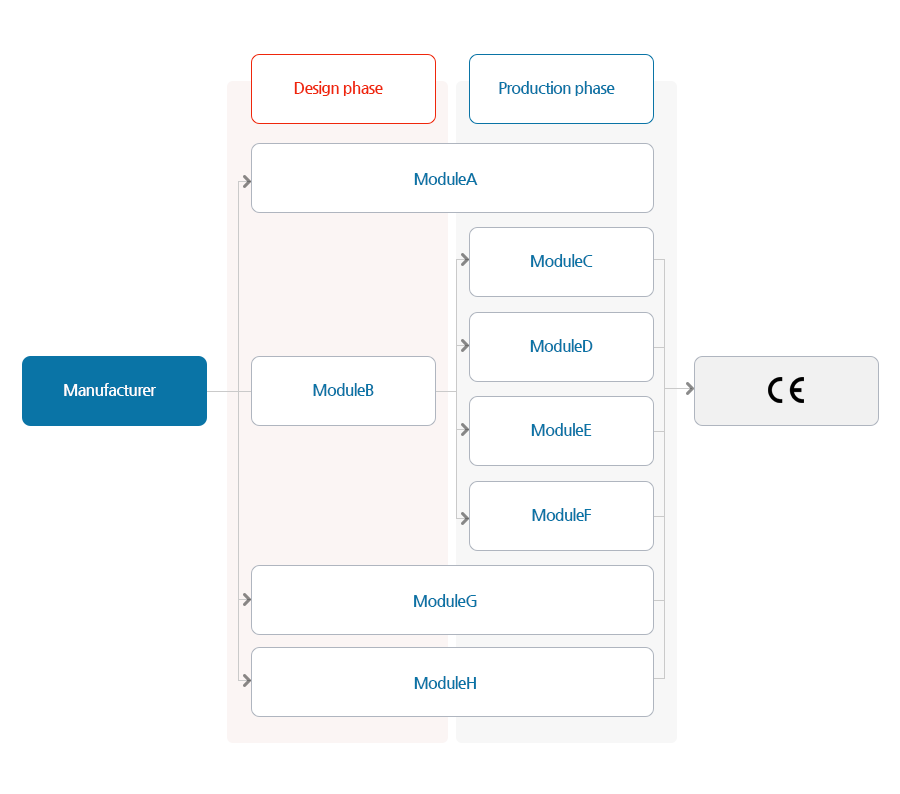

Conformity Assessment Module and Procedure

Organize / classify the conformity assessment method into eight modules (A to H) and classify them into seven standard inspection procedures based on the combination of each module. (A module can be selected according to the characteristic of each product) Conformity evaluation includes both design and manufacture, and D, E, H of a module must be ISO9000 certified.

Examination Module

| Modular Approach | |

|---|---|

| A (Internal Manufacturing Control) |

A requirement for internal control of the design and manufacturing of the Internal Control of production. The Notified Body's activity is not required. The manufacturer produces a technical document (TCF) on the design, manufacture, and operation of the product, and all measures necessary to guarantee the manufacturing process to ensure that the product conforms to its technical document and its requirements. Please take (For example, implementation of quality management system) |

| Aa1 (Internal Manufacturing Control-a1-) |

Module A is added to the test of one or more specific aspects of the final product and the Notified Body participates in the test at the design and manufacturing stages You |

| Aa2 (internal manufacturing control-a2-) |

Addition of unexpected product inspection by an authorized dealer (NB) to module A |

| B (EC Type Check) |

The EC type-examination maker must prepare a technical document (TCF) on product design, manufacture and operation at the design stage, and apply for an EC type check from a Notified Body. The Accredited Body (Notified Body) will test and evaluate the conformity and issue an EC form inspection certificate. |

| C (formal conformance) |

Conformity to type The manufacturer shall prepare, in the production phase, after module B, the conformance of the form described in the inspection certificate of EC type issued based on module B, No Notified Body activity is required. |

| C bis1 (form conformity-bis 1-) |

module C + Aa1 |

| C bis2 (conformation-bis2-) |

module C + Aa2 |

| D (Manufacturing Quality Assurance) |

Production quality assurance manufacturers intervene after module B by a Notified Body responsible for approving and managing the quality system of manufacturing, final product inspection and testing in the manufacturing stage. It is necessary to realize manufacturing quality assurance according to quality assurance standards, ISO 9001 (except for design, development, and management). |

| D bis (manufacturing quality assurance-bis-) |

Manufacturing quality assurance excluding module B |

| E (Manufacturing Quality Assurance) |

Production quality assurance manufacturers intervene after module B with a Notified Body responsible for approving and managing the quality system of final product inspection and testing in the manufacturing stage. , Quality Assurance Standard ISO 9001 (except for design, development and process control) must realize quality assurance. |

| E bis (manufacturing quality assurance-bis-) |

Quality assurance of products excluding module B |

| F (Product Verification) |

After the production verification module B, a Notified Body at the manufacturing stage manages the conformity of the format described in the EC type inspection certificate and issues a conformity certificate. You |

| F bis (Product Verification-bis-) |

Product Verification excluding Module B |

| G (Unit Verification) |

Notified Body at the design and manufacturing stage of Unit verification checks individual products and issues a certificate of conformity. |

| H (Full quality assurance) |

Intervened by a Notified Body responsible for approving and managing the quality system in the design, manufacturing, final product inspection and testing phase at the design and manufacturing stage of (Full quality assurance). Manufacturers need to realize full quality assurance based on quality assurance standard, ISO 9001. |

| H bis (manufacturing quality assurance-bis-) |

Complete quality assurance including design inspection |

Evaluation procedure

/ Ex Consulting / Accreditation / European Accreditation / Conformity Assessment Modules & Procedures

/ Ex Consulting / Accreditation / European Accreditation / Conformity Assessment Modules & Procedures