- About Us

-

Ex Training

Ex Training

-

Ex Training

Ex Training

-

Ex Training

-

Ex Consulting

Ex Consulting

-

Accreditation

Accreditation

- European Accreditation

- Korean Accreditation

-

Int'l Accreditation

Int'l Accreditation

-

Construction

Construction

-

Accreditation

-

Management System Consulting

Management System Consulting

- ISO Consulting

-

Occupational Safety & Environmental Consulting

Occupational Safety & Environmental Consulting

-

Occupational Safety Diagnosis

Occupational Safety Diagnosis

-

Ex Engineering

Ex Engineering

Management System Consulting

What is a Process Safety Management (PSM)?

PSM : Process Safety Management System

Process safety data, process risk analysis, safe operation plan and emergency action plan etc. based on Article 49-2 of the Industrial Safety and Health Law for business sites holding harmful hazard facilities where the risk of serious industrial accident occurrence is large It is a system to prevent serious industrial accidents by creating a report of the review, review and confirmation.

Process safety management Component

- Process safety data

- Assessment of process risk

- Safe driving plan

- Emergency action plan

- Other necessary matters (notification)

Process safety management Submission Destination

Target industries for the submission of process safety managements (Article 49-2 of the Industrial Safety and Health Act)

| Industry | Industry Classification Code |

|---|---|

| The crude oil refining industry | 19210 |

| Other petroleum refined water reprocessing industry | 19229 |

| Production of petrochemical basic chemical substances | 20111 |

| Manufacture of synthetic resins and other plastic materials | 20202 |

| Nitrogen compounds, nitrogen, phosphoric acid, and potassium fertilizer manufacturing industry | 20311 |

| Chemical fertilizer manufacturing industry such as compound fertilizer | 20312 |

| Manufacture of chemical and bactericidal insecticides and agricultural agents | 20321 |

| Chemical and fireworks products manufacturing industry | 20494 |

- ※Synthetic resin and other plastic manufacturing industry is limited when we correspond to the first or the second of the separate table 10

- ※Reflected in the 10th revision of the standard business classification in Korea (implemented from 2017.07.01)

- ※Synthetic resin and other plastic manufacturing industry is limited when we correspond to the first or the second of the separate table 10

51 types of substances targeted for submission of process safety managements (21 substances → 51 substances expanded for implementation on March 13, 2014)

※The specified quantities of flammable gas and flammable liquid are 5,000 kg for production and handling, 200,000 kg for storage

| Hazardous / Dangerous Substance Name | Specified Quantity |

|---|---|

| Flammable gas | 5,000 |

| Flammable liquid | 5,000 |

| Methyl isocyanate | 150 |

| phosgene | 750 |

| Acrylonitrile | 20,000 |

| ammonia | 200,000 |

| chlorine | 20,000 |

| Sulfur dioxide | 250,000 |

| Sulfur trioxide | 75,000 |

| Carbon disulfide | 5,000 |

| Hydrogen cyanide | 1,000 |

| Hydrogen fluoride (anhydrous hydrofluoric acid) | 1,000 |

| Hydrogen chloride (anhydrous hydrochloric acid) | 1,000 |

| Hydrogen sulfide | 1,000 |

| Ammonium nitrate | 500,000 |

| Nitroglycerin | 10,000 |

| Trinitrotlyse yen | 50,000 |

| hydrogen | 50,000 |

| Ethylene oxide | 10,000 |

| Phosphine | 50 |

| Silane | 50 |

| Nitric acid (weight 94.5% or more) | 250 |

| Fuming sulfuric acid (sulfur trioxide weight 65% or more and less than 80%) | 500,000 |

| Hydrogen peroxide (weight 52% or more) | 35,000 |

| Toluene diisocyanate | 100,000 |

| Chlorosulfonic acid | 500,000 |

| Hazardous / Dangerous Substance Name | Specified Quantity |

|---|---|

| Hydrogen bromide | 2,500 |

| Phosphorus trichloride | 750,000 |

| Benzyl chloride | 750,000 |

| Chlorine dioxide | 500 |

| Thionyl chloride | 150 |

| bromine | 100,000 |

| Carbon monoxide | 1,000 |

| Bonso Tree Chloride | 1,500 |

| Methyl ethyl ketone peroxide | 2,500 |

| Boron trifluoride | 150 |

| Nitroaniline | 2,500 |

| Chlorine tree puruorufa | 500 |

| Fluorine | 20,000 |

| Cyanuric fluoride | 50 |

| Nitrogen tree pull up freight | 2,500 |

| Nitrocellol male (flow rate to nitrogen 12.6% or more) | 100,000 |

| Benzoyl peroxide | 3,500 |

| Benzoyl peroxide | 3,500 |

| Dichlorosilane | 1,500 |

| Diethyl aluminum chloride | 2,500 |

| Diisopropyl oxidated carbonic acid | 3,500 |

| Hydrofluoric acid (1% or more by weight) | 1,000 |

| Hydrochloric acid (10% or more by weight) | 20,000 |

| Sulfuric acid (10% or more by weight) | 20,000 |

| Ammonia water (10% or more by weight) | 20,000 |

Submission Time of Process Safety Management

[Relationship of 3 in Enforcement Regulations Article 130]

Prior to installation of Hazardous Hazardous Facilities or change of major structural parts 30 days before construction start date

- Reflect the industrial piezoelectric display or the deliberation of the committee and the opinion of the worker representative

- When submitting a report for extension change, the same content as the existing audited content is exempt from submission.

Evaluation result of the implementation situation Defective workplace re-sent

The cause of the change The content of the report is complemented without delay

- For changes other than changing the main structural part

- ※2014.3.12 Hazardous and Hazardous Substances 30 additional target companies

- Five or more business establishments until September 13, 2014

- Business establishments with five or less members until September 13, 2015

Related Laws, Regulations, and Penalties

Related laws

- Sections 2 1 to 8 of Article 49 of the Industrial Safety and Health Act

- Industrial Safety and Health Act enforcement order Article 33 paragraphs 5 to 8

- Industrial Safety and Health Law Enforcement Regulations Article 130 paragraphs 2 to 6

Penalty matters

- Article 67-2 of the Industrial Safety and Health Law (3 years imprisonment or a fine of 20 million won or less)

- Unchanged when the change event occurred (Article 23-23 of the Industrial Safety and Health Act)

- Defective workplaces during PSM transition assessment (Article 28 of the Industrial Safety and Health Act)

- Article 72 of the Industrial Safety and Health Law (for over ten million won)

- Preparation of PSM and beach, submission failure (Article 49-21 of the Industrial Safety and Health Act)

- Does not comply with PSM content (Article 49-25 of the Industrial Safety and Health Act)

- Industrial Safety and Health Law Article 72 (less than 5 million won)

- If it has not been deliberated by the Industrial Safety and Health Committee in PSM,

- Industrial Safety and Health Act Article 72 (less than 30,000 won)

- If you have not received confirmation from the PSM drafting Secretary of Employment and Labor

Process Safety Management Consulting Procedure and Report Setting Materials

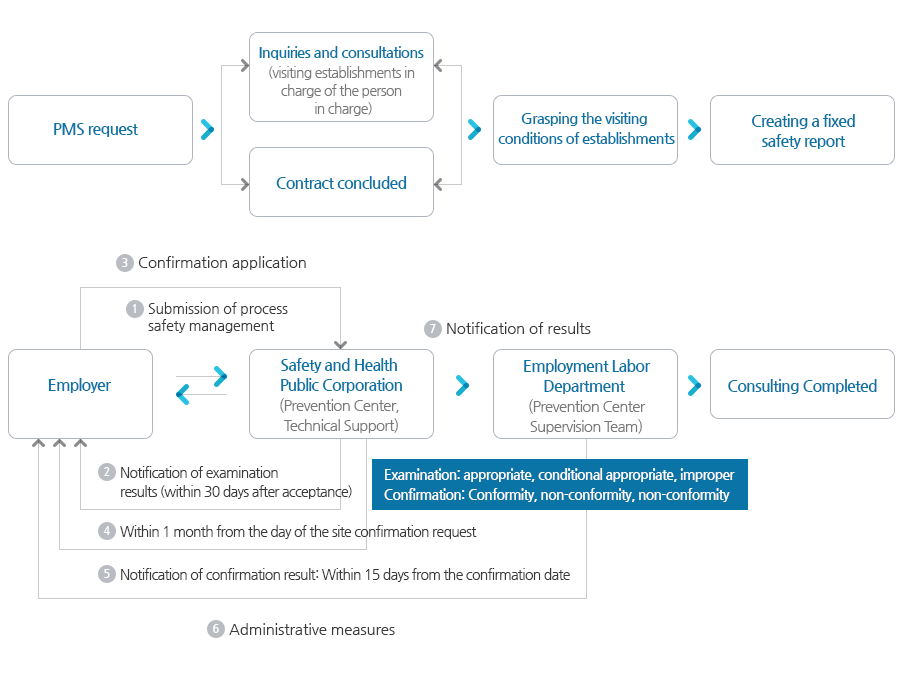

Consulting Procedure

Process safety management consulting configuration data

| Report content | basic data |

|---|---|

| Business outline | Business registration card / present condition of establishment |

| Process safety data | |

| Physical properties and usage of chemical substances | Handling and storage Use and storage amount of each chemical substance |

| Material Safety Data Sheet | MSDS of chemical substances |

| Material Safety Data Sheet | MSDS of chemical substances |

| List of power machines | Power Machine Design Data Sheet (Specs) |

| Equipment and equipment specifications | Device-specific design specification strength statement, ASS'Y. DWG |

| Piping and gasket specification | Piping and gasket specification |

| Safety valve and safety valve specified | PSV, BRV Design Data Sheet |

| Process manual | Process overview, process variables |

| PFD, P & ID and UFD | Drawing |

| Overall layout | Drawing (the plan of the whole process) |

| Building layout and hardware layout | Partial view (LAY-OUT drawing) |

| Building and iron structure drawing (plan each floor plan) | Floor plan and elevation of each floor |

| Fireproof structure specification | Fireproof material test report |

| Fire extinguisher installation plan and layout | Firefighting equipment specifications, capacity statement, and layout |

| Fire detection and alarm installation plan | Drawing |

| Gas leak detection and alarm equipment layout | Installation plan (current status and drawings) |

| Grounding specifications and grounding drawings | Grounding specifications, grounding statements and grounding arrangements |

| Installation plan of face wash and cleaning facilities | Installation plan (current status and layout) |

| Overview of the local exhaust system | Design criteria for the local exhaust system |

| Ventilation and Forced-Ventilation Overview | Overall ventilation and forced ventilation design criteria |

| Explosion-proof area division | Drawing |

| Explosion-proof electrical / instrument equipment specification and selection criteria | Design specification |

| Also electrical disconnection | Drawing and statement of short circuit capacity |

| Use the emergency power supply related drawings and the emergency power supply Load List | Emergency power supply design criteria |

| Safety design, production and installation related guidelines | Design, manufacture, and installation related codes and standards |

| Waste treatment design criteria and specifications | Basic data of design |

| Evaluation of process hazards | |

| Qualitative evaluation | The basic document of hazard evaluation such as P & ID |

| Accident frequency minimization and damage minimization measures | Examination of related parties |

| Quantitative evaluation | Basic data of evaluation |

| Risk analysis Attendant | Cooperation of specialized evaluators |

| Safe driving plan | |

| Safe driving instruction | Creation map-Operation MANUAL (Operation procedure manual including trial operation, S / U & S / D, normal operation, emergency operation, etc.) |

| Guideline for equipment inspection, inspection, maintenance, and maintenance planning | Equipment priority classification |

| Safety permit | Creation map |

| The management plan of cooperating company | Creation map |

| Education plan and training | Creation map |

| The procedure of check before moving | Creation map |

| Change element management plan | Creation map |

| Self-audit plan | Creation map |

| Accident investigation plan | Creation map |

| Emergency action plan | |

| Creation map | |

Review and Confirm Process Safety Management

Process safety management review

- Examination within 30 days after submission of the report

- The documents supplement period can be extended within 30 days, within the business owner's request 30 days

- Approved Process safety management Retention Period : 5 years

- Examination outcome

- Correct, conditionally correct if confirmed

- If it is inappropriate (return), the change order will apply for re-examination after the change is completed within 3 months

Confirm process safety management (6 of enforcement regulations Article 130)

- New equipment: once each in the installation process and commissioning phase

- Existing equipment: Within 6 months after the examination is completed

- On change: Within 1 month after the change is completed

- Confirmation and notification: Confirm whether to fulfill within 1 month from the date of confirmation request and notify the business owner within 15 days after confirmation

- Exemption of confirmation

- If you carry out your own audit of a person in charge of chemical-related subjects as an industrial safety advisor in the field of chemical safety or a person who holds a position of assistant professor or higher at a university and submit the result to the public corporation, Exemption from confirmation

- Special building safety inspection exemption: Regarding the submission of the safety report of the process, based on the provisions of Article 16 (Safety Inspection) paragraph 1 proviso of “Law on fire compensation and insurance participation”. , Exempted from the subject of "Safety inspection of special buildings and safety inspection of fire extinguishing equipment" conducted by the Korea Fire Insurance Association

- Electrical equipment periodic inspection: If the safety report of the process is submitted based on Article 32 of the Electricity Industry Law Enforcement Regulations Article 32 (target criteria and procedures of periodic inspection, etc.) and Schedule 10, the electric accommodation facility and the emergency spare The time of regular inspection of the power generation equipment is applied within 4 years

Examination procedure

- Examination body

- Within 1 month of reception (gas safety public corporation 15th, safety health public corporation 15th)

- Examination outcome

- Final notice within the establishment at the public corporation

- Confirmation procedure

- It is the same as the public corporation alone examination

- Multiple examinations

- Examination application

- Reception (gas safety public corporation)

- Examination schedule notice

- Examination

- Supplemental request

- Examination of supplementary documents

- Safety and Health Public Corp.

- Notification of examination schedule

- Examination

- Supplemental request

- Examination of supplementary documents

- Notice of examination schedule

/ Management System Consulting / Occupational Safety & Environmental Consulting / Process Safety Consulting / PSM?

/ Management System Consulting / Occupational Safety & Environmental Consulting / Process Safety Consulting / PSM?