- About Us

-

Ex Training

Ex Training

-

Ex Training

Ex Training

-

Ex Training

-

Ex Consulting

Ex Consulting

-

Accreditation

Accreditation

- European Accreditation

- Korean Accreditation

-

Int'l Accreditation

Int'l Accreditation

-

Construction

Construction

-

Accreditation

-

Management System Consulting

Management System Consulting

- ISO Consulting

-

Occupational Safety & Environmental Consulting

Occupational Safety & Environmental Consulting

-

Occupational Safety Diagnosis

Occupational Safety Diagnosis

-

Ex Engineering

Ex Engineering

Management System Consulting

What is a Hazardous Protection Plan?

Prior to installing, relocating or changing any construction, machinery, equipment and equipment directly related to the production process, prepare and submit a hazard risk prevention plan, and review safety in advance, ensuring source safety It is a statutory system to contribute to the maintenance and promotion of occupational injury prevention and worker health and safety.

Systems and Related Laws

Based on the Industrial Safety and Health Act Article 48, paragraphs 1 and 2, the employer of the business corresponding to the type of industry and scale determined by the Labor Ministry Ordinance, etc. When establishing, relocating, or changing its main structural parts, hazardous protection plan shall be prepared and submitted to the Secretary of Labor as required by the Labor Ordinance.

- Industrial Safety and Health Law Enforcement Order Article 33-2

- Industrial Safety and Health Law Enforcement Regulations Article 120-Article 124-2

- If you do not create and submit a hazard risk prevention plan in violation of the provisions of Article 48 (1) to (3) of the Act, a fine of 10 million won will be imposed

Business Place Targeted for Submission

Target industry

- Manufacture of metalworking products (except machinery and furniture)

- Non-metallic mineral products manufacturing industry

- Other machinery and equipment manufacturing industry

- Car and trailer manufacturing

- Food manufacturing industry

- Rubber products and plastic products manufacturing industry

- Wood and wood products manufacturing industry

- Manufacture of other products

- Primary metal manufacturing industry

- Furniture manufacturing industry

- Chemical substance and chemical product manufacturing industry

- Semiconductor manufacturing

- Electronic parts manufacturing industry

Increase in changed facilities and incidental facilities, etc. due to expansion of facilities and replacement or remodeling before establishment of a business establishment with a total of 300 kW or more of electricity contract capacity

Target equipment

In the case of manufacturing establishments, when installing or relocating the following facilities or changing major structural parts:

Melting furnace (metal or nonmetal mineral)

- When installing or relocating a melting furnace with a capacity of 3 tons or more

- If you increase the melting capacity of the existing melting furnace, change the type of heat source or the internal structure,

Chemical equipment

- When setting up or transferring special chemical equipment that handles more than the standard amount

- When replacing, changing or adding target special chemical equipment to increase production of existing special chemical equipment

- ※What is special chemical equipment?

- ⁻ A reaction apparatus (reactor) in which an exothermic reaction occurs

- ⁻ Devices that perform separation such as high-grade, rectification, evaporation, extraction etc. where the inside of the device is operated within the danger concentration of explosion

- ⁻ Equipment operated with the temperature of the substance to be heated being higher than the decomposition temperature or the ignition point of the dangerous substance being heated

- ⁻ Equipment that may generate dangerous substances due to abnormal chemical reaction such as reaction runaway.

- ⁻ Equipment operated at high temperature (350 ° C) or high pressure (980 KPa) or higher

- ⁻ For heating of chemical substances (burner)

Drying equipment

The following drying equipment with a maximum heat consumption of 50 kg or more per hour, or a maximum power consumption of 50 kW or more based on a heat source

Gas collective welding equipment

Fixed gas collective welding equipment with fixed flammable gas concentration of 1,000 kg or more

Hazardous substance and dust work related equipment for permission and management

- Newly or relocated a local exhaust system with a capacity of 60 m3 / min or more for related equipment that handles 49 types of substances subject to permission or management (targets for safety inspection), or add hoods, ducts, air purification sheets, and blowers; When changing

- Handle substances other than 49 of the substances to be managed, or build or relocate a local exhaust device of 150 m3 / min or more at the dust dust working place, or add, change or change hoods, ducts, air purifiers, blowers If

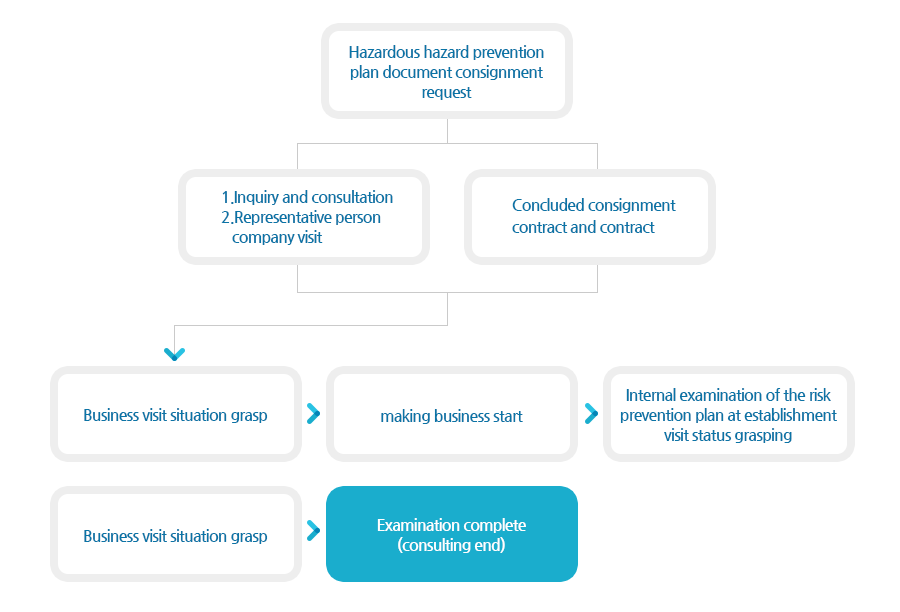

Consulting Procedure

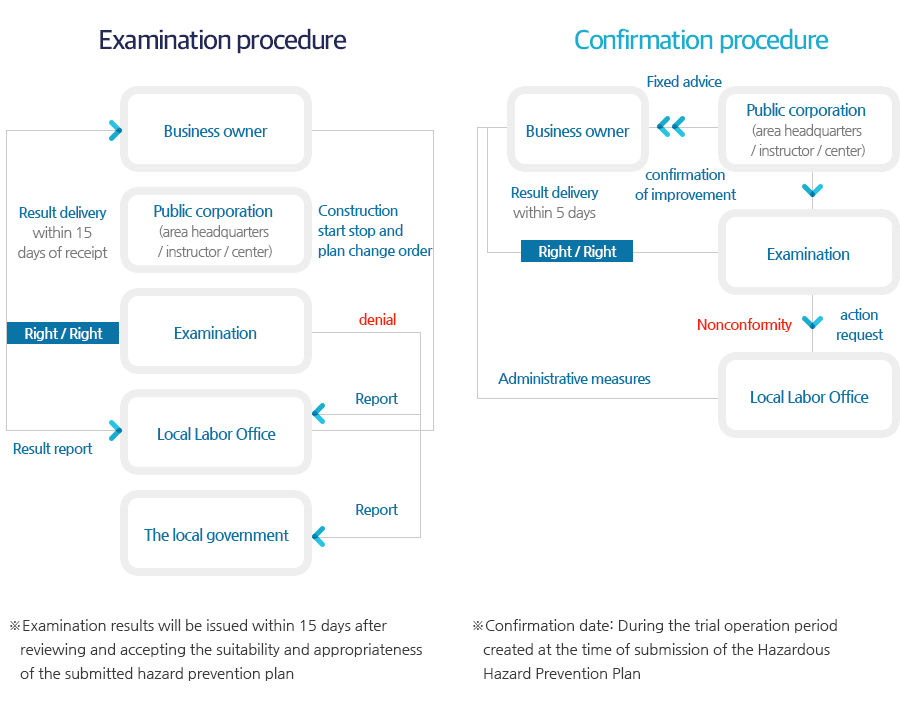

Examination and Confirmation Procedure

Submission Time

Until 15 days before the construction start

- ※Clause 4 of Labor Department notification 2008-82 Article 2 (definition)

- ⁻ "Construction start work" and the submission site of the plan document This means the start of construction work to install or relocate constructions, machines, equipment, facilities, etc. or change the structure.

Consulting Effect

- Producing instruction based on quick knowledge and information

- Fine and quick creation through specialized skills and human resources

- Reduce inappropriate factors in the examination

- Maximize the work efficiency of the person in charge by outsourcing and shorten the time

- Ensuring safety by identifying risks in advance in the workplace

/ Management System Consulting / Occupational Safety & Environmental Consulting / Hazard Protection Plan

/ Management System Consulting / Occupational Safety & Environmental Consulting / Hazard Protection Plan